While it’s easy to remember all the bad things that happened in 2020 (and there were

quite a few), the fact is that our wonderful supporters just like you helped

make it The Trust’s best year ever and we plan on keeping that momentum going

through 2021 and beyond.

We Did It!!

A Trust supporter challenged our followers last September, pledging to match

$50,000 if it was raised by the end of the year. In an astonishing show of your

support, we not only met our goal but exceeded it by nearly $10,000, bringing

our total donations to over $100,000.

From all of us, we want to thank each and every one of you, no matter how much or

how little you gave. Whether it was one dollar or a thousand, your donation counted,

got us over our goal and another step closer to getting 5550 on the rails.

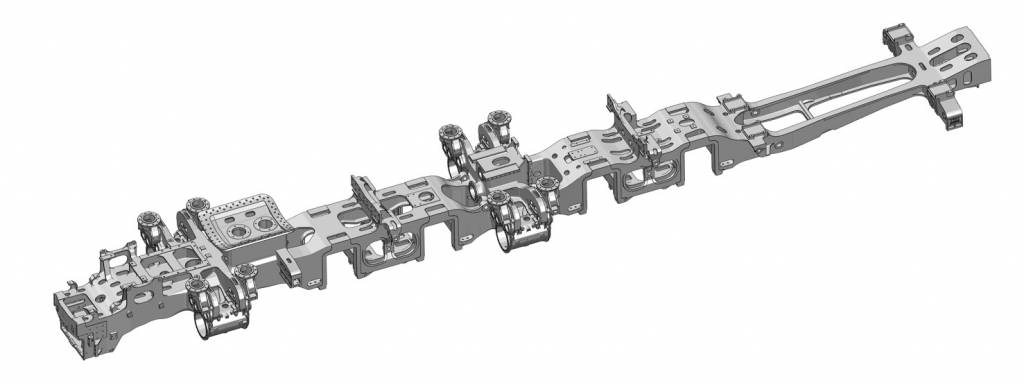

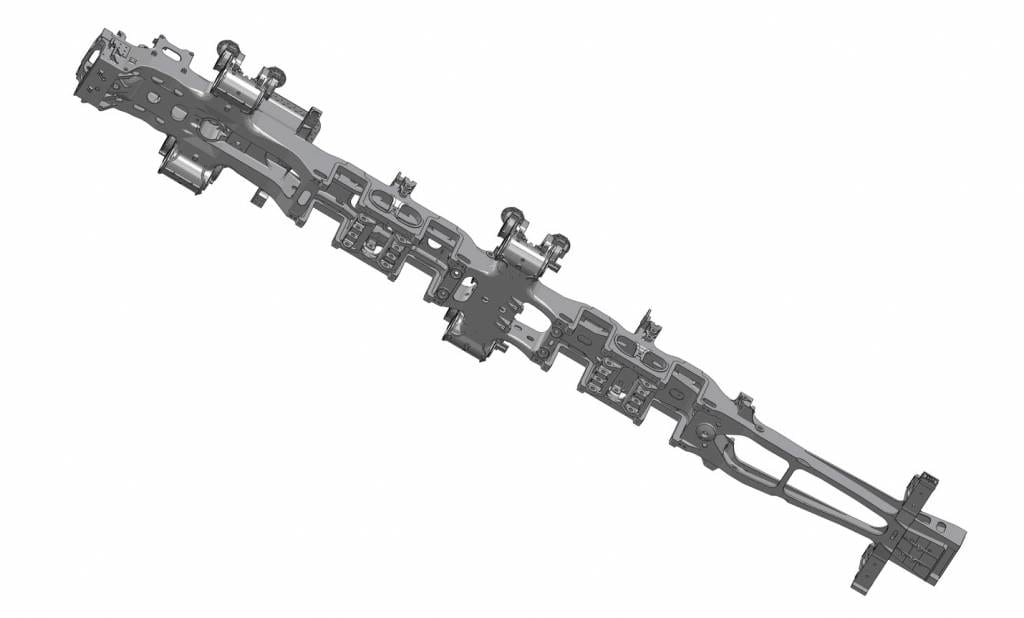

Frame CAD is Complete

The amazing employees at JakTool logged over 1,000 working hours bringing the T1’s

frame from the actual pages of history into a fully rendered CAD model that

will help us forge this amazing design in steel. The resulting computer file is

the largest single rendering JakTool has ever done. Take a moment to admire the

beauty and hard work that went into reviving the backbone of the T1.

Frame seen from the front right, looking back

Frame from the top. Front is at left, rear is at right

Frame from the bottom. Front is at left, rear is at right

Firebox Update

Steam Services of America in Sylva, North Carolina has been hard at work fabricating the

foundation ring of the firebox, also known as the mudring. Once this component

is complete, it will be shipped to Ohio where firebox construction will take

place. After that is finished, the entire firebox assembly will be off to Saint

Louis, Missouri where it will join the rest of the boiler.

Backhead

As mentioned above, once the foundation ring arrives in Ohio, it will enable construction of

the firebox to commence. One component of the firebox is the backhead which is

home to all the controls that face the engineer and fireman and the opening

through which coal is shoveled.

Our general manager, Jason Johnson, seen here stands 6 feet (1.82 meters) tall to provide a

sense of scale to this massive piece of metal.

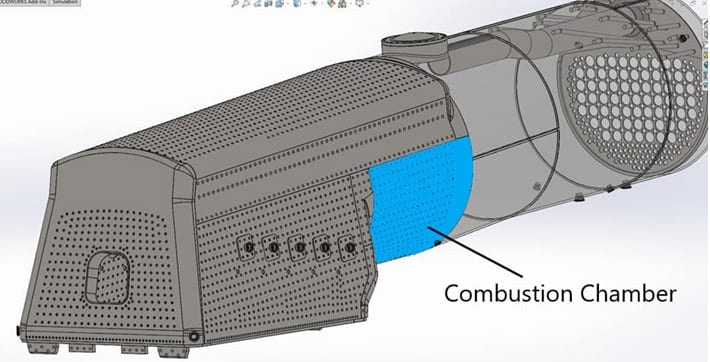

Combustion Chamber

Another piece of the puzzle coming together at Continental Fabricators in St. Louis, Missouri is

the combustion chamber portion of the boiler/firebox assembly. The final image

shows where this part fits into the locomotive.

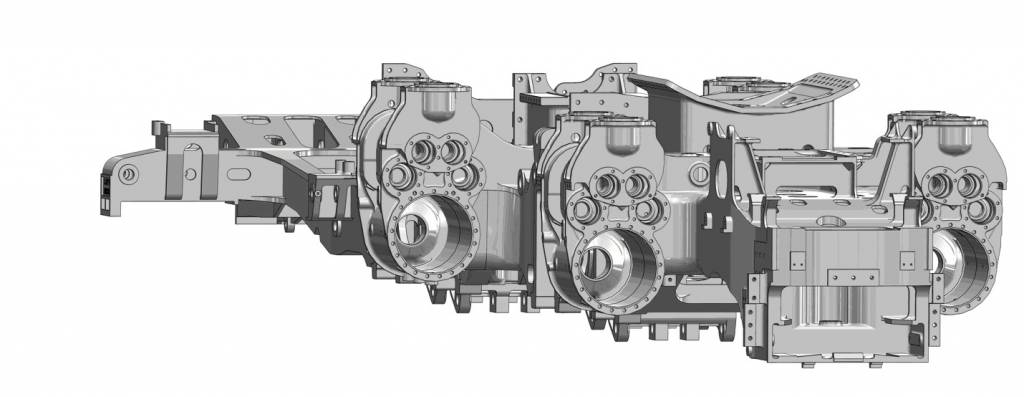

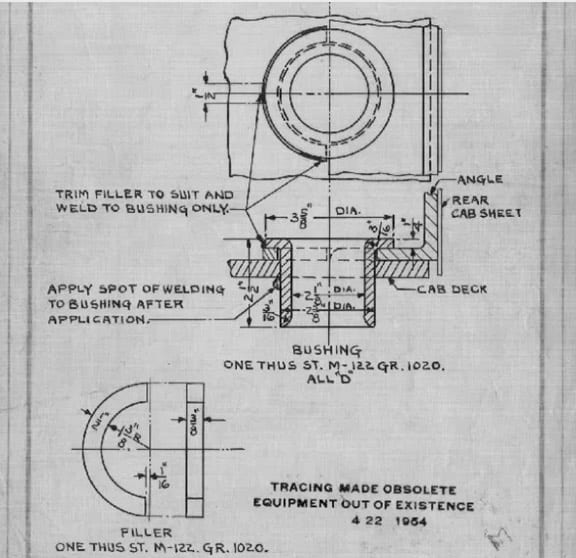

Guess That Part!

To test your T1 knowledge, let’s see if you can figure out what this part is just by looking at

these drawings. We’ll reveal the answer in the next issue of The Trail

Blazer.

Here’s a hint…you probably have one of these close by or in your hand right now.

Let’s Keep it Going!

Thanks again to all of you who helped make 2020 the Trust’s best year so far. Momentum is our

friend in seeing 5550 completed in steel and we can’t keep that momentum up

without your continued support. Let’s make 2021 even better than last year…in

more ways that one!