Winter 2022

Supporters like you helped make 2021 the best year ever for The Trust, just like you have every year before. Here’s to a successful and healthy 2022!

Another Record Fundraiser in the Books

In September, we challenged you to help get us to $150,000 for our year-end fundraiser and you went above and beyond, taking us to $160,402.26. We cannot begin to thank you all enough…your donations are building 5550, no matter the size.

Throat Sheet Delivered

Contractor FMW Solutions was instrumental in getting 5550’s throat sheet, which is the front section of the firebox) fabricated and shipped to St. Louis where it will be joined with the remainder of the firebox. This remarkable achievement bent ¾” thick steel into shape using a McCabe Flanger without heat.

This boiler plate steel had to be bent to 86.7 degrees and perfect overall dimensions on an inside radius. Did we mention

they didn’t use heat?

Thanks again to FMW Solutions for their incredible work!

Dry Pipe Completed

This impressive 14-inch (35.56 cm) pipe carries dry steam inside the boiler to the throttle.

An Interview with Norman Beaver

Mr. Beaver set about creating his own scale T1 and was kind enough to speak with us about his process as well as sharing some photos of the finished product.

The T1 Trust: Why don’t you start out by telling us a little bit about yourself, and where you grew up and all that fun stuff.

Norman Beaver: I’m Norman Beaver from the Washington DC area and grew up just north of DC in Montgomery County and still live just outside of DC in Prince George’s County now, which is Beltsville, Maryland. I was a surveyor by trade, worked in heavy

construction, and I’ve been retired for about eight years and my main hobby is building standard gauge trains.

T1 Trust: So, would you say you consider yourself a model train enthusiast?

NB: Yeah, I’ve been into train collecting since 1972. My dad was a big train collector and my brother is also, and the T1 that I built in standard gauge is something I did for my brother. I think it was about build number seventeen of the different motorized units that I’ve built.

T1 Trust: So, what led you to do a T1?

NB: It was something that my brother was interested in. He’s a big fan of Pennsylvania Locomotives and Pennsylvania

Railroad. And I’ve always leaned more towards the B&O stuff, but this was something that he was interested in and unlike the actual T1, it has both sets of drivers are swiveling and that’s to negotiate the tight turns that we have in tin plate railroading.

T1Trust: That makes sense.

NB: It’s a really neat piece. And the tender was made from scratch, and it’s kind of unique, the way I made the trucks on it, it actually use four, four trucks and kinda Siamese them together, so they articulate in pairs.

T1Trust: Huh? Interesting.

NB: And it’ll go around a tighter turn that way, so it’s actually like a piece on each side, it just… That kinda hangs over and fills in the gap that actually slides slightly back and forth.

T1 Trust: I just love when people come up with creative… Excuse me… No, no, I really do. I think it’s neat what people will create to get something built. And you’re an example of that.

NB: Yeah, it’s fun being retired, so I’m always just… The planning part is really the most fun, and the building is fun too, but the planning it is really exciting, ’cause it… I just sit there and dream up all the possibilities.

I had built another articulated engine that was a similar design, so I was confident that I could build it. And he had a shell from what is, what’s Lionel’s Hiawatha locomotive that they built back in the ’90s, I guess. And anyway, I took that, the cab on that was very similar to the cab on the T1. So, I used that as a starting point and just really had to do a lot of modifications to it. I can send you some pictures of the build of it if you’re interested.

T1 Trust: Yes, that’d be wonderful. If you could also send me a step-by-step as to how you did it, we’re very impressed with what you built.

NB: Okay, sure. Yeah. I can send you something like that. I think it might be included in the new book that’s coming out on modern standard gauge railroads. Railroad models that have been built since about the 1960s, stuff that was built post World War II. And I think it might be included in that, that’s coming out in the spring, I believe.

T1 Trust: Okay. Do you happen to… Do you happen to know what the title of that book will be?

NB: I’d have to look. It’s modern standard gauge, but I don’t, I’m not sure the exact title. But I can send that to you. I do have the title, but I don’t… I can’t think of exactly what it is off hand.

T1 Trust: That’s fine. So why don’t you tell us a little bit about the other models you built?

NB: It started out with a B&O the model of the tunnel locomotive that they had it from 1895. That was the first engine I built. And since then, I built the articulated engine and then the model of the George Washington, which is one of the Baltimore and Ohio

Pacifics that they built in 1927. And then a bunch of other stuff like switchers and speeders, a Mac speeder and Mac rail bus and the CP Huntington. I made a model of that, which is really nice. That’s out in the Sacramento, California, Rail Museum.

T1 Trust: I went there when I was a kid. It was quite the experience.

NB: Yeah. I haven’t been out there myself, but I’ve seen pictures of it.

T1 Trust: It’s pretty amazing.

NB: So, another one that I had at that, is a model of the John Quincy Adams, which is the B&O Grasshopper, that’s out in Ohio, in some museum. They have a couple of grasshoppers in the B&O Museum in Baltimore also. And that’s pretty entertaining and…

T1 Trust: Now you’ll have to explain to me, I’m actually not… I hate to say it, I’m not familiar with that term “grasshopper”, what does that refer to?

NB: Well, the Grasshopper was the very first series of successful locomotives that the B&O built back in early and mid 1830s.

T1 Trust: Oh, wow.

NB: And it’s got a vertical boiler and cylinders, and then it’s got arms that transfer the power about five different- ways to get to the wheels. And it’s got beams that are worked by the cylinders, that works a push rod that goes down to a crank, on a gear drive, and the second gear runs a counter shaft that goes out and then there’s cranks on that, that goes to the wheel, so it’s quite a contraption.

T1 Trust: Quite a bit of energy loss there.

NB: Yeah, I don’t know. I think they just kept adding stuff on till they got it to work, but they were actually pretty successful, they built about 18 of them, and the last ones actually operated all the way up to 1892. They were still used as yard locomotives in Baltimore.

T1 Trust: Oh wow, that’s amazing.

NB: So, yeah, and just, it’s more amazing that they’ve actually saved a couple of them, so.

T1 Trust: Yeah, especially back then. You don’t see a lot of preserved stuff from those early days.

NB: The B&O Museum has one and so it’s quite a treasure trove of old stuff there.

T1 Trust: Didn’t they have a roof collapse in a snowstorm some years ago?

NB: They did, yeah. It’s probably 15 years ago now. Yeah, it was quite the catastrophe, but they’ve re-built it all and most of the locomotives that got damaged were repaired.

T1 Trust: Did you know about the T1 Trust prior to building that locomotive for your brother?

NB: I just found out about it while I was building it and I didn’t know about it till my brother told me about it. He was very aware of it, but I didn’t know about it. But, yeah, it’s really cool. So eventually got the cab built and some of the running gear now, and they

procured a tender that’s, save them a little bit of money, as such, cut and needs lot of rebuild right now.

T1 Trust: Yeah, the tender is actually in surprisingly good shape. It had… It was just used as a water tank, and I believe, well, I haven’t seen it with my own eyes, but I believe the hatches were welded shut, so the interior is actually in very good condition considering its age. We currently have it parked in upstate New York awaiting work, but as for the rest of the locomotive, we’re just wrapping up on the boiler, we have a couple of the driving wheels, we have the cab, the prow with the headlight, and we’re carrying on with the frame.

NB: Yeah, yeah. Well, it was fun building the one that I did, I had to… The casting that I used, the Hiawatha casting was… It’s like a zinc, I think, so you couldn’t weld to it, so I had to build like a substructure underneath and a tap and drill and tap into that to extend that out, and then I had to add about five and a half inches on the front and used a piece of three-inch exhaust pipe for the rest of the boiler on the front. [chuckle]

T1 Trust: Hey, if it works…

NB: Yeah, it worked great. So yeah, just a lot of cutting and welding, and it’s always slow building the first one

when you’re doing something like that, because it’s kind of a design-build and as you go. And I did have experience with the, like I said, having two swivel motors, so, that I had some experience with, so I knew what I was up against there, but it turned out pretty good, there’s a guy named Jim Waterman, that’s in our standard gauge module group that… He is kind of a low production

manufacturer, whereas I’m just a tinkerer and builder of one-off stuff, and he has got a casting of a T1 that he’s going to make a series of them. They’re about two or three inches longer than the one I built and a different front-end, He used a real early front end that they had, and I used like a later, like the production front that they used to have.

T1 Trust: Yeah, that flatter front design.

NB: Correct. I’d be glad to send you some of my pictures of the build and a little run down on it.

T1 Trust: That would be wonderful. I’d love to see it. So, I know your brother’s really the PRR enthusiast, but how do you feel about reviving a T1?

NB: Oh, that’s just amazing, it’s crazy. [chuckle]

T1 Trust: I agree.

NB: They got that Western Maryland Articulated working again.

T1 Trust: I saw that.

NB: It’s running next month, I think.

T1 Trust: That thing needed a lot of love.

NB: Yeah. Yeah. But man, making something from scratch, that’s pretty crazy.

T1 Trust: Well, it’s certainly been a heck of a ride.

NB: Well, I imagine casting the frame is gonna be a mammoth undertaking…

T1 Trust: Well, we’ve actually looked into that, and what we’ve done is the company that has done the CAD for the frame, is currently working on figuring out the best way to build it as it’s actually going to be cast in two pieces and then welded together,

NB: Oh, okay.

T1 Trust: We did find some companies that could do a single piece casting, but it was going be extraordinarily expensive and with modern welding techniques, maybe not even necessary.

T1 Trust: So, it’ll be very interesting to see when it’s finished though.

NB: Wow, that’s really exciting, and I’m sure it’s gonna be a long haul to get it… Get all that together.

T1 Trust: We got another eight years or so, if we stay on schedule, but we’ve come this far.

NB: Well, I’m 72 tomorrow, so I might live to see it.

T1 Trust: Well, happy birthday to you.

NB: Thank you. I’m still in good shape right now, so hopefully I’ll be around to see that, that’d be great.

T1 Trust: Well, do you have any questions for me?

NB: No, I don’t think I do.

T1 Trust: Well, thank you again for your time, I really appreciate it.

NB: Sure, yeah. I’m sure it might make an interesting article for you guys anyway.

T1 Trust: Most definitely. Well, have a fantastic birthday and thank you again for taking the time to speak with me.

We’d like to thank Mr. Beaver once again for taking time out of his day to speak with us. Below you’ll find photos he provided of his scale T1.

Guess That Part

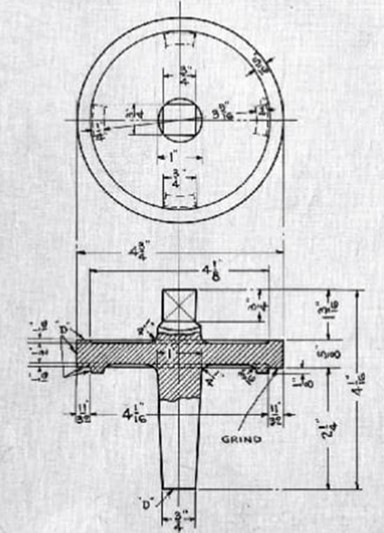

In the last issue, we challenged you to identify this section of an original T1 part drawing.

This is part of drawing F413512 which shows the boiler injector check valve cap.