Summer 2022

The first normal summer in three years has let us get back out and back to normal and at The T1 Trust, we’re working even harder than ever to bring America’s newest mainline steam locomotive to life.

The T1 Comes Home to Pennsylvania

In mid-May, we joined the freshly painted cab up with the mostly-completed boiler and the decorative prow for a jaunt to the PRRT&HS’s annual meeting in Harrisburg, Pennsylvania. The event was a huge success for all involved and allowed the public and our supporters alike to get a feel for just how big 5550 will be once it is complete. Also, Lerro Photography was on hand to bring the T1 to life for the camera and we’re sure you’ll agree that the results were spectacular. For all who were able to come by and say hi, thank you!

All joined up with the prow and the cab and ready to hit the road!

Keeping Things Rolling

At the beginning of the week, we picked up two more of the massive driving wheels that will propel 5550 down the line. These wheels were cast at Beaver Valley Alloy in Monaca, Pennsylvania (as all our others have) and had been on display at the Youngstown Steel Heritage Museum and Railroad.

Frame Design Wrapping Up

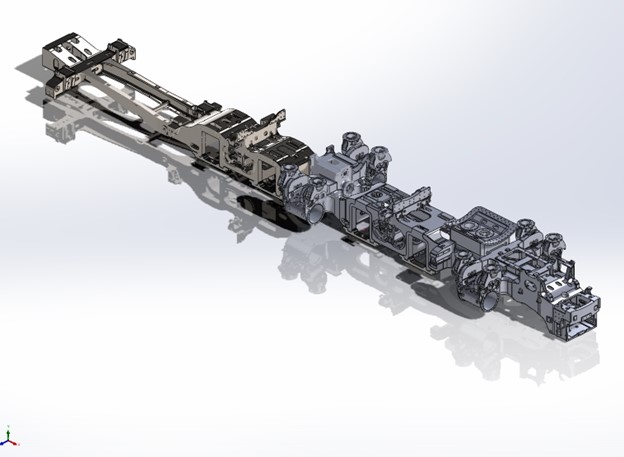

One of the longest-standing and most frequently asked questions we get is ‘What about the frame?’ There’s no arguing with the incredible engineering that went into the single piece cast locomotive frames in the waning years of steam. While it would actually be possible to reproduce this achievement today, the truth is that it is easier and more cost-effective to cast the frame in two pieces and then weld those parts together as welding technology has advanced tremendously since the last T1 was built in 1946.

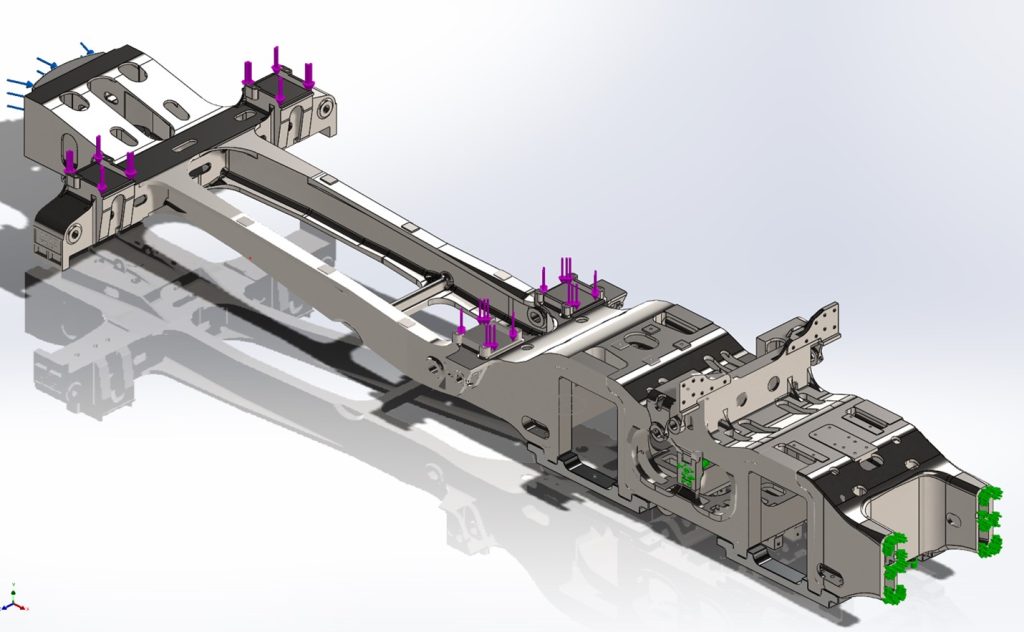

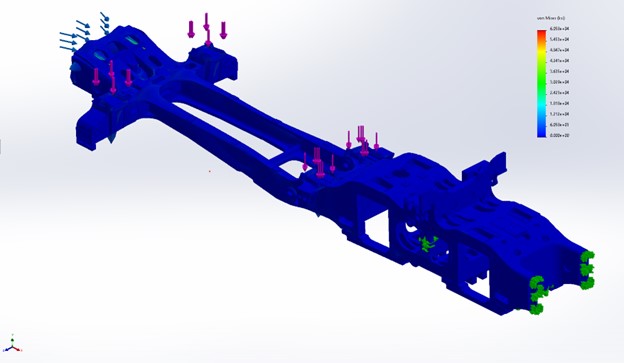

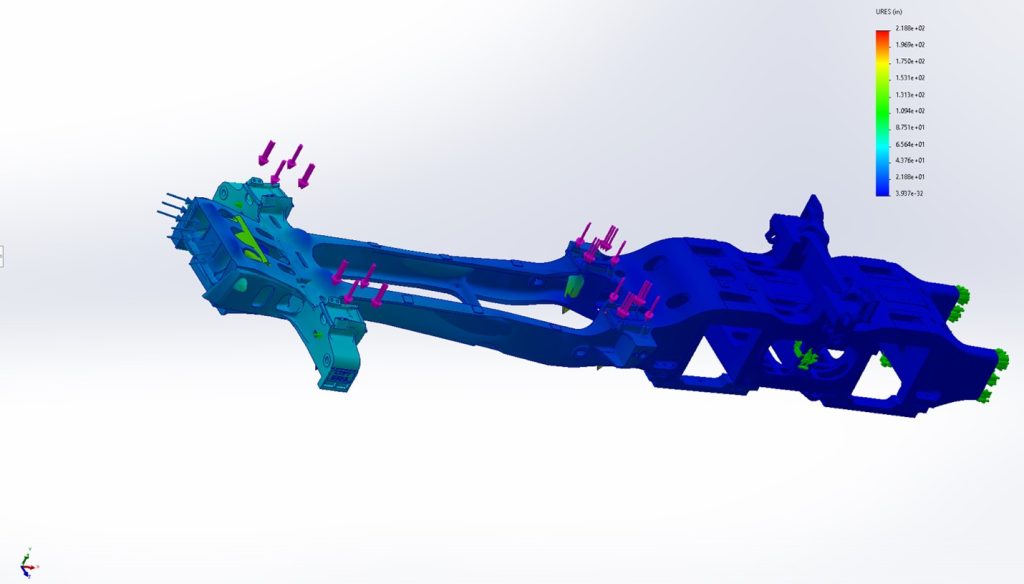

Over the last few years, we’ve been putting computer aided design (CAD) to work to simulate the loads and stresses that the frame receives and how those forces travel through it during acceleration, turning, and braking. These simulations allow us to not only assure a perfect fit of the boiler to the frame but also enable us to simulate the transmission of those forces through a two-piece, welded frame design and section those two pieces accordingly.

Below you’ll find drawings that show not only how CAD visualizes the forces that the frame is receiving but also how it’s helped us ensure a better mating with the pedestal caps than would have been possible if we’d simply followed the original PRR drawings.

The above two images give a sense of where stresses are developing in the rear frame section under the million pound “squeeze” test load case. This is an early run. Part of the engineerng is looking at how the stresses develop and making sure the loads and boundary conditions are giving us “real” results. Sometimes the results tell us we need to make adjustments to the boundary conditions or how a load is applied.

The complete frame model showing how we “cut” the frame using “planes” at the sections we think will be good for making the welds. Depending on how the stresses develop, we can easily shift the planes fore and aft to see if/how the stress profiles change and thus assure ourselves about the location of the welds.

Whistling on the Western Maryland

While the boiler, cab and prow were on their way home from Harrisburg, 5550’s whistle (certified as an original T1 whistle) spent a few weeks at the Western Maryland Scenic Railroad on former Chesapeake & Ohio 1309. It was wonderful to hear 5550’s voice played by steam and echoing through the hills of Maryland and we can’t thank the fine folks at WMSR enough.

Frame Club Announcement

The T1 Trust is excited to be launching our Frame Club. This will be the single biggest, most complicated and challenging fundraising Club we will offer you to be a part of. The last couple years we have spent working in the background leading up to launching the Frame Club to our members. This will be our biggest fundraising ask in the seven years we have been working on this project.

We are nearing the end of the exterior boiler construction and we will continue that to completion while also working on the frame simultaneously.

JAKTool out of New Jersey completed the first phase of the frame by modeling the as-built frame. The PRR T1 Trust has hired FMW Solutions to finalize the engineering and do stress analysis on the final design. We will share with everyone the final design which we expect to be a combination of welded pieces and large castings. We feel this is the most efficient and economical approach.

This final phase of the frame engineering is expected to take up to 9 months with all the stress analysis. This means that we are likely to start cutting steel for the frame this year (2022) We have located and narrowed down our frame construction company to two certified companies and our mechanical committee members will meet with and interview these companies in the next couple months to decide who is the best fit for the PRR T1 Trust.

The total design and engineering phase of the Frame is $140,000. We have raised through donations and in-kind contributions $115,000 to date. We have $25,000 left to raise to complete engineering. That is expected to be complete in the Fall of 2022. Early estimates for the frame look to be around $900,000 to complete. We have currently raised $65,000 for frame construction.

Contributions can be made in any amount. You can set pledges up on a monthly recurring charge. (For example, you want $250/month to go to the Frame Club for 10 months.)

- All contributions over $1000 will receive all the benefits of the Founder’s Club.

- Contributions over $25,000 will get their name engraved in the frame

- Contributions over $50,000 will receive their name engraved in frame as well as a cast Bronze #5550 Number Plate

This will be the biggest opportunity for you to help us out. Your contribution will go to what many have said would never happen. Here you are making it happen. No one person is funding this project, rather thousands of railfans just like yourself.

An Interview with Dave Kloke

A legend in the steam community in his own right, Dave was kind enough to take some time out of his busy schedule and talk to us about not only 5550 but his own new-build steam locomotives.

T1 Trust: Okay. Why don’t you start out by introducing yourself?

Dave: Well, my name is Dave Kloke and I’m a fabricator mechanic.

T1 Trust: Just to walk us through your early life a little bit, your childhood, where you grew up and what your parents did?

Dave: Well, we were in the ready-mix concrete block business when I was younger, and I started off making concrete blocks when I was pretty young. And then we got a ready-mix business going and we ran that until I was about 18 and then my father got married again, so there was little room for me.

[chuckle]

T1 Trust: So, you were out on your own at that point, huh?

Dave: Yeah, I was on my own by the time I was 18. I started driving a truck, back and forth to Ocala, Florida for a guy out of Wisconsin. So that’s what I did. And I bought my first End Loader and got a construction business, started out like everybody else in a dump truck and a track end loader and just worked up from there. Ended up with probably about forty pieces when the economy went bad, and I got out of that and got into building locomotives. So that’s how that all evolved.

T1 Trust: So, you said you got into building locomotives, you were responsible for constructing… If my memory serves, it was two. Correct?

Dave: Actually, we just finished the Bock too.

T1 Trust: Okay.

Dave: I reconstructed that. So, I did the Leviathan, the York and then we did The Bock number one, I just finished that. And they’re running now, they’re all running. We had a few issues with The Bock but we got through it. We didn’t have any prints for that engine, so we built that off of the line drawings. It was all we had.

T1 Trust: Wow.

Dave: So that was a really tough engine to build. It was tougher than the other two because the other two, I had all the prints and everything for it, so it was all easy. O’Connor did a wonderful job with the prints and everything really fit together well. So good engineer, he was a good engineer. Some people like to bash him a little bit, but he did a good job. The two at Promontory Point still run after 30 years, of course they don’t pull anything but they still run every day, so.

T1 Trust: And you built those two engines for Promontory Point? Those were built in California, weren’t they?

Dave: No, I didn’t build those.

T1 Trust: Oh, you did not?

Dave: I used the prints from those two.

T1 Trust: Okay, I’m sorry, I misunderstood. My apologies.

Dave: Yeah, I might have brought that across. Anyways, I used the prints of the patterns from those two engines, from O’Connor Engineering.

T1 Trust: So, what are your impressions of the T1 and the Trust and all that we’re doing?

Dave: It’s a hell of a job. It’s a big undertaking and it’s gonna be a nice engine when it’s done. I think it’s just unbelievable the size of it, that’s what gets me and how far it’s coming and how you’re getting the money for it.

From what I hear, you’ve got the bearings donated and he got a really good price on that boiler. And I understand the boiler’s pretty much paid for and done and they’re going on to their frame and that’ll be a big undertaking and I told him where to get the springs. I found a really good place in Canada that makes springs and I’m hoping he can use those people because that’s a big project for that. I’m sure those springs are going to be very expensive for that engine.

We had 36 springs on the Lincoln [funeral] car and I forget how much they cost but it was pretty good chunk of change and they’re a lot smaller, of course. But I just told… I know Crystal Winters got a set of springs from the same outfit and they built it for the Lion, they built a complete set for the Lion, so they’re good at making railroad springs. So that and just to find the people that can do it. Every once in a while, that occasional call or we’ll talk about it and find… I’ll tell him where he can find some stuff, get it done. But that’s getting harder and harder to do too.

T1 Trust: It is. This is like putting together a giant jigsaw puzzle based on a photo from 1942. [chuckle]

Dave: Right. Right. Well, I just did one and it was a smaller version but The Bock was a real… Like I said, it was a pile of parts when we got it and no drawings, just a line drawing.

T1 Trust: Well, you think about it, if we had decided to build the T1 and we had not been fortunate enough to have the number of drawings for this engine that we have, we’d effectively been doing what you were doing and pretty much designing it from scratch.

Dave: Right. But you have quite a few drawings on that engine, don’t you?

T1 Trust: Correct. The Pennsylvania State Archives in Harrisburg, I believe they have over 90% of the drawings for the T1.

Dave: That’s wonderful because that’s a really good start.

T1 Trust: It is.

Dave: When I started building the Leviathan, I had a friend that called for the prints and he has the original prints from O’Connor Engineering. I told him what I was gonna do and he thought I was just another crazy person. He figured he was going to have to copy about 800 drawings and send them to me and I’d never do anything with ’em. So, he told me that the Park Service had the patterns, and I should go there first to see if I could get them, which I did to build the two engines actually. So that worked out well and then I found out that you could get the prints out of the archives in Denver and that Park Service would print those. You have to pay for the printing, but they’ll give you the prints. So I did that so we ended up with a full set of drawings on both engines, on Leviathan and York.

T1 Trust: Those engines were fairly similar in design. Were they not?

Dave: Well, they were close. The boilers were a little different, not much as far as they were a little longer, smoke box was different, and the frames were a little different and I think the York has a tilt on the cylinders.

Anyways, that all worked out and the wheels came out well so I talked to a couple people that worked on the engines for O’Connor and they gave me a lot of good advice and they had… A few of the issues they had I learned about before we got into it. So it’s always good to listen to somebody that’s been through it.

T1 Trust: Exactly. That’s why we like to get with the people. It’s a pretty short list of the people who have done this but the ones who have yourself included have been very, very supportive and very gracious.

Dave: Well, yeah, absolutely.

T1 Trust: How did you first learn about the T1 Trust?

Dave: Well, Jason was doing my contracts for me when I was at the Leviathan on the road. So I’ve known Jason for quite a while. I met him in the Quad Cities, and he rented my engine in Quad Cities. But anyways, he and I had lunch one day and I asked him if he’d do the contracts for my engine when we were running around, because he had a lot of experience and he knew a lot of the railroad people. He also knew the ones you could trust and the ones you couldn’t and there are some of them shysters out there too.

T1 Trust: Oh, they’re everywhere.

Dave: I’m sure you’ve ran into a few of them already.

T1 Trust: We’ve had a couple. [chuckle]

Dave: Yeah. That’s how I got to know Jason and then when he started building the engine, I just paid attention, I went to see him a couple times and went to look at the wheels and the boiler, last time I was there he had the fire box sheet there and he had those laying in the backyard and he’s since sold that shop, I guess, so.

T1 Trust: He has.

Dave: I don’t know, where is he working out of now?

T1 Trust: That’s a very good question. I don’t actually know. From what I can gather, I think he still maintains an interest in his shop but I don’t know if he still owns it.

Dave: Okay. Well, I wish you a lot of luck. It’s a lot of work and it’s a huge project.

T1 Trust: Thank you. It really is. But I’ll tell you, I’ve been part of this since February of 2014 and it’s been fascinating to watch the perception and the level of support change from people telling us oh, you’re crazy, that’s impossible, you can’t do that to people coming from miles away to just see this thing sitting in a parking lot.

Dave: Well and I hate those people who say it’s impossible. I had a great uncle said that there ain’t no such thing as ‘can’t’. Just get it done.

T1 Trust: Exactly.

Dave: So, he taught me that early on when I was young and I’ve always kind of went by that, just get at it, get it done. You can make it work. So anything… What else can I tell you? Just…

T1 Trust: Just a couple more questions and I’ll let you go. I know you’re a busy guy.

Dave: No. I’ve got time. It’s at the end of the day and the only thing I don’t have a Miller Lite in my hand yet, so.

[laughter]

T1 Trust: Well, that’s an easy thing to fix. [laughter] What do you… I know this is a little more for the earlier stages of the project but obviously this thing isn’t done yet. What do you think are the greatest challenges that the trust faces and how do you think they might best be overcome?

Dave: Well, the biggest problem is insurance, I’m sure. Insurance and then get trackage to run it on, that’s gonna be a big issue, because we don’t… Most of our tracks belong to some foreign entity, or the Canadian National controls a lot of trackage and they don’t like steam, so well, that’s the issue. I think it’s gonna be an issue to get it around the country. Now, Union Pacific, they can run on their track anytime, anywhere but you guys don’t own your own unless you get Warren Buffet involved.

[laughter]

So yeah, I think that’s one of your issues, the insurance and the trackage, so.

T1 Trust: Alright. Is there anything else that you… Any other advice that you would like to give us?

Dave: No, I think you’re doing a wonderful job managing this and getting it together.

T1 Trust: Well, thank you and I apologize it took us so long to get together and get this interview in the books.

Dave: No, that’s fine. That’s fine. We’re all busy and gotta keep going. Any other information you need from me, I’ll be glad to give it to you.

T1 Trust: I much appreciate it. You have yourself a great week now.

Dave: Yep. You too.

T1 Trust: Thanks.

Dave: Bye now.